Re-route Water Direction for 4A-GE 20v Engine from FF Chassis to FR Chassis KE70 or AE86

22nd February 2005

This write up is for owners of Toyota Corolla KE70 or Levin / Trueno AE86 or similar Rear Wheel Drive / FR platform (Front mounted engine but Rear propulsion system) who wish to use the Toyota 4A-GE 20v (20 valves) engine with Quad (4) throttles + VVT running AFM (AE101) or MAP (AE111), which was originally designed for FWD / FF platform.

Due to the engine moving from a FF chassis originally mounting the engine in transverse configuration changing to longitudinal for FR chassis there is a problems with installation due to: -

Problems

Solution 1 to Problem 1

The distributor hitting the firewall issue can be easily solved via knocking the firewall and mounting the engine slightly forward. This upsets the balance somewhat but not significant. The deficit can be correct via handling setup i.e. suspension or anti-roll-bar or chassis strengthening etc. There are other solutions apart from this one.

Regardless, the water routing system is not as easily solved. Often long running water pipes are laid either above the hot extractors of right under the quad (4) throttles, which takes up allot of space.

In my case the water route was previously run above the exhaust extractors and were not very efficient in terms of cooling as well as aesthetics, not to mention extra weight of water and pipes. So It is now changed to AE86 style and the way to do it is: -

Solution 2 to Problem 2

First cut existing water pipe from head to water pump and re-weld to modify direction. The water pipe is made of cast aluminum hence aluminum welding is required. Not normal weld.

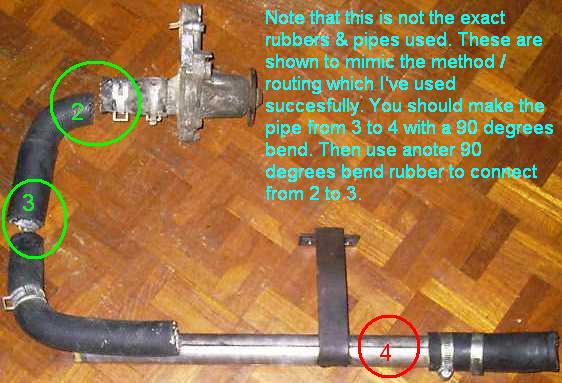

Second make a 90 degrees bend pipe and find a 90 degrees band rubber - something like this: -

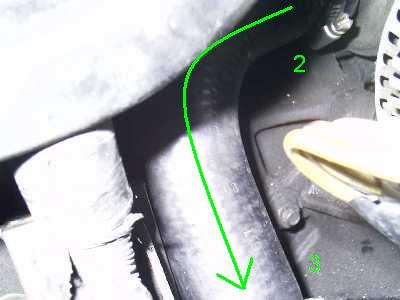

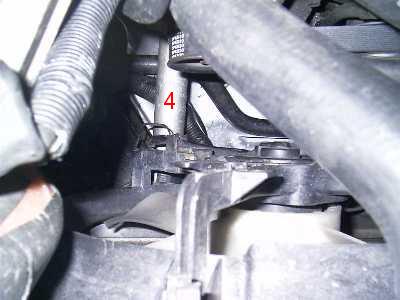

Individual pictures of the completed installation are: -

Finally make a "90 degrees turn" pipe to route the old water outlet back into the old water inlet. I had a spare pipe like above and cut it to weld onto existing old water outlet mouth. Use another 90 degrees turn rubber to complete the "U-turn".

Another picture showing hot water out right under throttle 1 and a little bit cold water in at the bottom right hand corner. The clip can be just about seen.

Aftermath

28th February 2005

It is important to report that the conversion is a major success. There is no water heating problem. The engine runs perfectly fine, no bad reaction what-so-ever. It's a perfect conversion because it is the lowest cost also the easiest and fastest within hours :)

High rev no problem. Stuck in traffic jam in very hot afternoon surrounded by many other hot cars. No water heating at all.

OK OK, may be because I've got a big ass oil cooler. The oil temperature normally stay at 70 Celsius. High rev gets it up to 83 Celsius at the highest and it goes up really really slowly. Morning 8:30 am drive to LRT station to pick up colleagues then get stuck in traffic queue for a while then drive to NPE highway and go at 160 and reach the office in no more than 10 minutes from LRT. Oil temp still 50 Celsius :)

There is also no leaking - obviously :) hahahahhha

There is no issue with the direction. I seriously don't know which is which, i.e. cold water going into head first or block first. There is no need to change the head gasket from 20v type to 16v as well. It is a major success and I should have done it since day one.......................................

ACOUSTICS SECTION AUDIO SECTION CAR SECTION

HOME - Technical Website for Acoustics, Audio and Car