Engine Tuning

Part 2 - Replacing OEM fuel pressure regulator (FPR)

2nd May 2003

Disclaimer : - for stock EFI system, actually there is no such thing as "tuning".

Please remember to read Part 1 before proceeding.

Once the OEM fuel pressure regulator was replaced by aftermarket adjustable unit and set to 40 psi with vacuum. The idling increase from 900 rpm to 1,300 rpm. This suggests that the previous unit was faulty???

The specifications for Fuel Pressure Regulator are: -

28 psi at idling with vacuum

40 psi without vacuum, also equals to full throttle

Notice

the above 40 psi compared to original 28 psi. This is the fault for not reading

the manual properly and carefully ![]() hahahaahhaah

hahahaahhaah

It

is no wonder why the idling shoot up so high ![]() hahahahahaha

hahahahahaha

Update 16th February 2004 - Lately it is found that this particular transplant is a bit weird because every time after the ECU lost it's memory, the start up idling will be extremely high until the ECU is fully run-in. The run-in conditions may be: -

slow drive - takes two weeks

moderate drive - takes one week

fast drive in the track - takes 30 minutes

It is guessed that the ECU needs to sense all working conditions and in all ranges then reset accordingly. This is especially relevant to the O2 sensor, because it only works properly over 600 Celsius. This is why driving hard run-in fast because the O2 sensor is hot enough. Please see www.autoshop101.com technical articles regarding O2 sensor.

This was not know during the installation therefore lead to all the troubles below. So many mistakes below. But it is a good read so not to fall into the same trap.

This time try to compensate using TPS again, but without success as the TPS angle setting was already MINIMUM and cannot be turned further.

This was very worrying, as the followings were done: -

synchronized the 4 throttle butterflies

synchronized the 4 throttle's vacuum

changed a new TOYOTA OEM fuel filter

distributor timing around 8 degrees within factory spec.

TPS at MINIMUM

known good fuel pump

known good Vane Air Flow Meter (AFM)

etc etc etc

There is nothing else to mess with (I think), the fuel

pressure regulator was the last one (I think). ![]()

Unless the following item(s) are considered defect (which I don't believe): -

water temperature sensor for the ECU, not radiator fan switch nor meter gauge

ISCV (Idle Speed Control Valve)

VSV for EVAP (E = Evaporative)

exhaust sensor 1

exhaust sensor 2 (not-connected)

etc etc etc

But the car ran nearly perfectly previously, achieved many full tank of 40 liters for 400 km travel, therefore everything seems to be in order.......

Anyway, the mechanic who installed the new adjustable fuel pressure regulator then help to reduce the idling. He saw me mess with the throttle opener's (see 4AG-E 20Valve Engine Repair Manual page FI-50 & 51 top reference screw.

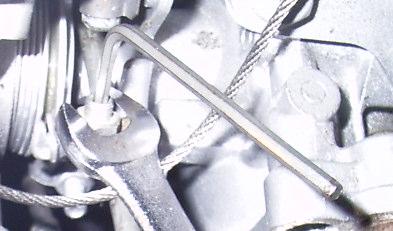

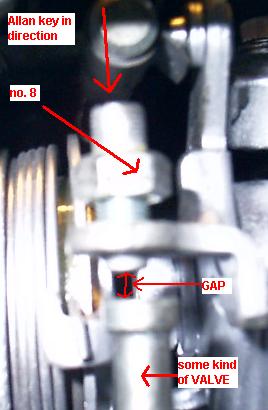

Adjust using no.8 + Allan key

Adjust using no.8 + Allan key

Normally this cannot be seen, especially for FF case, but once the air intake surge tank is removed and the throttle is wide open, this "little" "nut & screw" above the throttle opener will appear in the middle section of the 4 throttles.

So the installer messed with it as well, but no matter what he did there was ... literally no chance, idling at best drop to 1,100 rpm

Side notes [I forgot to mention, during the fuel pressure regulator (FPR) change. I disconnected the ECU to erase it's memory of error logging and my driving behavior.]

Extra

info 13th June 2003 [the throttle opener will re-tract downwards

around 5 mm once the engine starts, no wonder there was no effect ![]() ] {If

anyone knows why / what is the function / the correct setting for this, please

email me and thanks a million in advance}

] {If

anyone knows why / what is the function / the correct setting for this, please

email me and thanks a million in advance}

Then (by stroke of luck), he adjusted the AFM's by-pass valve and the engine idling sound changed to lower rpm, but the meter still shows 1,100 rpm.

The mech. was quicky requested to wait and explained to him that this ECU is (stupid, crazy, weird) etc that it will react - slowly - to certain changes.

After 30 seconds or so, (may be sooner) the idling drop

to 900 rpm. Perfect ![]()

We mess with it a little after that, (the usual itchy hand), but was not necessary, just the usual final touch thing.

![]() yeah, so home

it is, the next destination

yeah, so home

it is, the next destination ![]()

The mech. also notice there was allot of free-play on the

throttle cable bracket, so he tighten it ![]()

The drive feels very good,

more attention was paid on

1,800 rpm, 3,000 rpm, and 5,000 rpm and notice the engine sound changed from

before, not only that but power feels a little bit different (can't say for sure

better or not?). Definitely not more HP, but

smoother power delivery. Don't know, will have to wait till another Dyno Day ![]() .

Please see Dyno Day to find out the

HPO, AFR and torque of this car.

.

Please see Dyno Day to find out the

HPO, AFR and torque of this car.

But.......some how??? some times???? the idling is not correct, crazy, radical, sometimes very normal, after a few turn, very high..... weird.... not happy :( cause no consistency............

3rd May 2003 Afternoon & Evening

Drove to work, not good at all. Sometimes high sometimes normal. Lots of small pinging while driving around 3,000 to 4,000 rpm all gears. On the evening before moving on, the distributor timing was reduced further and now is estimated around 6 degrees.

After working hours, straight to my mech.'s workshop and open the engine hood and guess what? The cause of radical idling was found.

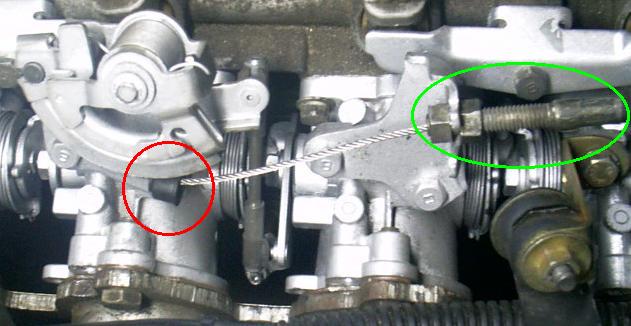

Notice the rubber high-lighted by the red color circle. It was that rubber that slip in and out of the throttle that caused the idling to run high and low. A mistake for not cutting it out after the mech. adjusted the tension.

But, the throttle cable was also noticed to be too tight and that the accelerator cannot be depressed fully. i.e. normally the accelerator can reach the bottom, but now it can't. Meaning when the accelerator is half-way down, the throttle would be fully open. The only problem with this setting is that if the driver is always radical and slamming the accelerator all the time. The throttle cable would break very quickly due to abuse. (learned from Bill Sherwood)

Therefore a friend's help was requested to depress the accelerator fully, where the new true full throttle cable bracket position is found and set. The new result is: -

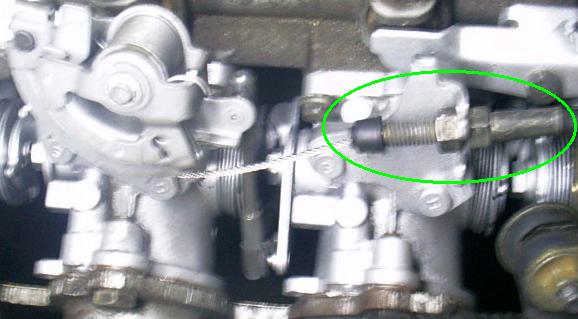

Notice the distance difference? and that

the rubber insulator can be re-inserted so that it does not fall out to mess with the throttle. So

it didn't

have to be cut after all ![]()

The old setting before this was realized is: -

During this time the AFM's Flap tension was reduced 1 notch. The AFM's by-pass valve was also messed with here and there, so much until where is where is forgotten. :(

Drive home and it doesn't feel right :(

Night, 11pm till 3am

A new pair of wiper blades was provide, so change it it is.

And this is where the itchy hand troubles starts again. Since the car is being messed with, and that the idling / performance / setting was not satisfying.

Therefore ....................... here it goes again.

The DMM (digital multi meter) was used to check the TPS and found it was way out of spec, but don't know why???

Later on it was realized that the DMM's internal ohms error was not taken into account. When turn on, it cannot read 0 (zero) ohm, it was giving either 0.3, 0.4, or 1.9 sometimes. After the error was subtracted the results look good, but this wasted some 1 hour of time. :(

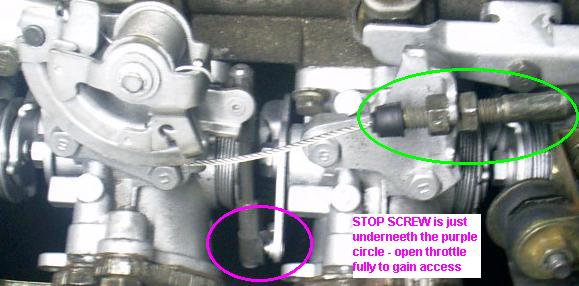

Then the nut and screw right above the throttle opener (see 4AG-E 20Valve Engine Repair Manual page FI-50 & 51 was messed with.

It was thought that it would affect idle. The correct setting is un-known, even after reading / looking at the 4AG-E 20Valve Engine Repair Manual page FI-50 & 51 many times. Still something has to be done in hope that it would work. Regardless, something(s) will be learned from it (I hope).

After another hour of "behind-my-mind" thinking. The understanding came to a point where the screw should just sit on-top of the throttle opener when the butterflies are fully closed.

So, to do it, the

screw was released from touching the head of the throttle opener. then retighten it very

slowly and carefully, so not to turn so much as it push hard down onto the head

of the throttle opener and force the butterflies to open. This took

another hour or so.....(lack of experience mah ![]() ) and finally got it work. Recheck the

TPS using the DMM and all is fine.

) and finally got it work. Recheck the

TPS using the DMM and all is fine.

Disconnected the ECU from the battery to erase memory, reconnect the battery and start the car.

Naddddddddddddddddddd........................... the stupid engine now idles at 1,300 rpm. After 10 seconds or so it reduce to 1,200 rpm and finally after another 30 seconds or so reduce to 1,100 rpm.

This is still too high, 3am it is and gave up it was and bed to go next. :(

4th May 2003 Afternoon

BTSC was next destination, without bordering about the idling, there was just no more solution to use. So in go to the track and RAN RAN RAN, spun spun spun, tire wear wear wear, aiyah sakit hati..... (sakit hati is malay language = pain heart = heart sick in english)

Oh nevermind, the idling now seats around 750 rpm or 850rpm or so. What the fuxk?????

Must be the stupid ECU, must drive hard then it will adjust itself more properly???

Or is there something still wrong???

Anyway, the summaries are: -

TPS at MINIMUM

AFM's Flap tension remains at 4 notch

AFM's by-pass valve fully close, (i.e. all the way down)

distributor timing around 6 degrees

new fuel filter

fuel pressure regulator at 40 psi no vacuum, 31 psi with vacuum.

Well, still long way to go...............

Power not that powerful, more to come in the future if there is any updates ![]()

Aftermath

6th May 2003

Just went to Kuala Kangsar from Petaling Jaya. Travelled 516 km and used 41 liters of BP ron 97 fuel, sustaining at 120 on 5th gear. Some 50 km was city driving

This is quite good (I think), although some other owners may have better mileage.

Therefore keep trying - lets see when can it go 600 km distance using 40 liters???

By the way, if any automotive engineer is seeing this,

especially from TOYOTA's 20v department. Please email me and give me some tips

![]() I desperate need them

I desperate need them ![]() I'll do anything for it

I'll do anything for it ![]() hahahahahhahaha

hahahahahhahaha

ACOUSTICS SECTION AUDIO SECTION CAR SECTION

HOME - Technical Website for Acoustics, Audio and Car