Cold Air Intake

24th January 2004

Surprise ................................... guess what it is made of?

ta da .......................................

Hahahahah, I wonder who else have thought of this ridiculous DIY solution .......??? hahahahaha

But first test - does the air filter fit in?

Hahahhah it does .......

what a luck ..........

Hahahhah it does .......

what a luck ..........

Before proceeding, the air filter is cleaned first: -

Soaking in washing powder seems to be quick and easy. The water immediately turn dark.

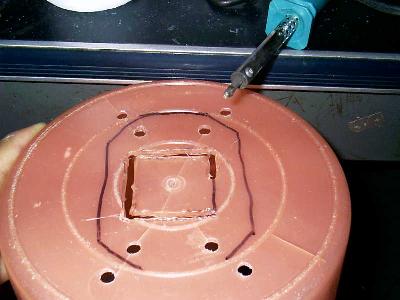

Now to make screw holes and air inlet hole.

Using AFM rubber and previous adaptor plate as template. Drill the eight holes and cut the middle square opening.

The soldering iron is used to melt it's way through to cut the air inlet hole.

And the cutting is complete together with the small corner for "by-pass" tuning in the future. Can do without.

Install the AFM 1st then install the air filter last.

Last come the most difficult thing to do. Slowly put back into the engine bay and cut away extra plastic. Trial and error solution is used. Many cuts were used by solder iron and cutter. Not a perfect cut.........

The green arrow shows the "guessed" easiest entry. Unfortunately the picture is a bit dark at that point.

The green arrow shows the "guessed" easiest entry. Unfortunately the picture is a bit dark at that point.

However future "little" pieces of plates can be made to cover the smaller sections / areas to further dissect the hot air from cold air. Not too difficult after that. But not yet do it. hehheeh lazy men :)

And finally coloring for further heat shielding. Silver is known to reflect heat best. Again not yet do it. busy lah :(

Ultimately a completely different and better intake plenum / manifold will be made in the future ..... I wonder when will I have the time and $$$$ ...... :)

ACOUSTICS SECTION AUDIO SECTION CAR SECTION

HOME - Technical Website for Acoustics, Audio and Car