Distributor Re-location to the front

Some time in July 2002 - Updated 26th February 2004 - Updated 22nd April 2008

Update 22nd April 2008

Around the Q1 of 2004 or 2005 the relocator above is removed just for aesthetic sake, where the distributor is put back into original place. Careful observation of the "Socket" that sits onto the cam pulley on the "Groove" part found that the soft aluminum has been eaten away by constant high-end beating by the harder material of the distributor's T shape reader. Hence if a relocator is to be used, make sure all the material are hard type.

This quickly explains why my engine suffer unstable power delivery, because as it is accelerated, the reader is pushed ahead, while during deceleration, it is pushed backwards. The gap / tolerance suppose to be zero degrees ideally, in reality closely matched to 0.0x but for the eaten away groove, there's probably as much as 5 degrees.

Imagine a free-floating distributor angle of 5 degrees, the supposingly smart ECU is constantly self adjusting to optimise bestly, but couldn't. What a mess.

Original from July 2002

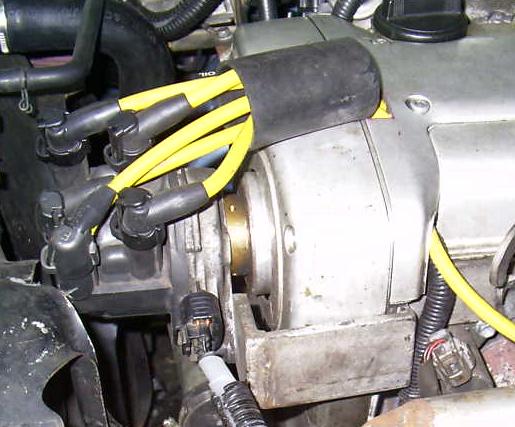

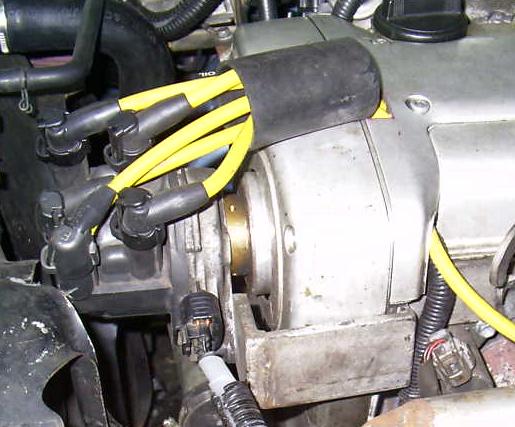

The picture basically speaks for itself. In simple term, the distributor sits into a insert which then sits into a high speed bearing (air-cond compressor's bearing), which then sits into a socket, which sits and stick (reference) to the pulley.

Recipe: -

The high speed bearing could just be seen in the picture above sticking out of the original plastic cam covers.

The INSERT is the copper color thingy with 2 M3 nut holes.

The distributor measuring head (sort of like T shape turning head) sits into a groove, which is made on the socket. Please note the groove that turns the T head, is slightly off-axis. Machinist will know it means.

When the original pulley turns, it turns the socket as well, hence the groove force the T-shape head to turn and the distributor get a signal.

The distributor is then supported by the large bracket.

It sticks out allot, not as neat as the Japanese, but this cost is very much lower compared to the Japanese.

Still a distributor less ignition system from a 4A-GZE (twin / waste spark) is more desirable. Or a Direct Ignition System (DIS) using Coil over Plugs (COP) would be even more desirable.

2 out of 4 spark plugs' wire will not be long enough.

The firing order MARK on the distributor is now wrong and has to be changed to 1243 if I'm not mistaken. However this does not mean that the engine's firing has changed. It still remains 1342. Please don't get confused.

ACOUSTICS SECTION AUDIO SECTION CAR SECTION

HOME - Technical Website for Acoustics, Audio and Car